There are so many little details the regular person does not know is responsible for his comfort. These things are best described as backstage operations but highly determines the outcome of the very things we admire around us.

In this article, we are going to discuss one of such, as well as (briefly) highlight our top 3 companies responsible for supplying the services.

Without keeping you in further suspense, this article will explain the importance of sputtering targets. Just in case you are not aware of what it is, do not be too quick to leave.

This is because products such as (some) glasses, solar panels, electronic chips… and many more around us are products of the sputtering target.

What Is Sputtering Target?

Using a technique called thin film or sputter deposition (as the name implies) is all about the creation of thin films using suitable materials that undergo the right condition. For more on what the process entails, you can read this.

What Is the Conventional Sputtering Target Process?

As stated earlier, the sputtering process requires the use of suitable materials that undergo several chemical interferences.

Although it is a long-used procedure that dates back to 1852, there have been several changes and modifications. However, certain things are still peculiar to the technique. One of such is the process of breaking from concentrated solid-state to substrates.

The substrate is tinier particles made from the earlier concentrated solid state. This is achieved with the aid of gaseous ions that allow the item to end up as a coat or spray for other materials.

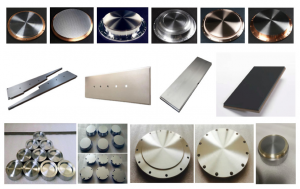

What Is the Composition of Sputtering Target?

Regardless of the modification in techniques over the years, we have established some peculiarities of the procedure. For instance, they all require the help of gaseous ions in breaking down large solid materials into tinier bits.

Now that you are aware of this, you should also know that the composition of the technique is heavily dependent on the eventual use. For instance, the composition when intended for making glass will differ from what you will have with an electronic microchip.

Be that as it may, sputtering target compositions are largely metallic as they come in various elements and even alloy.

Peculiar to the electrical and electronic sectors, the compositions are often various forms of copper alloy.

This is because of the impressive feature of copper as a conductor. However, because of the flaw with oxidation and structural strength, copper is mixed with other elements or materials. This is called a copper alloy.

Other than the various forms of metallic elements and alloys used, options such as ceramic can be part of the sputtering target composition. When ceramic is involved, it is mostly in making certain tools that require the procedure.

Size of Sputtering Target

There is no one size fits all sputtering target product. The size of the sputtering target is largely dependent on the thin film created, as well as the eventual product it is made for.

Even at this, generally speaking, the size of regular sputter targets ranges from 2.5 centimeters to 0.9 meters in diameter and length respectively. Of course, exclusion from this range will be for exceptionally thin film and eventual products to be created.

Another factor that determines the size of the sputtering target is the equipment used to make it. Some equipment can only process large final products. This means the sputtering target can only be large.

If the product is small by design, manufacturers can outsmart the system by using special joints to attach various smaller connected targets.

However, this is not an easy process and ideally, it should be used only as last resort. This explains why equipment is a major determinant of the size of the sputtering target.

In light of this, people who require the services of manufacturers and suppliers must be certain they have the required machinery to create the needed product. This way, the outcome will be good.

What Determines the Effectiveness of the Thin Film or Sputtering Disposition?

The gaseous ion(s) that breaks down the solid material and (physical and chemical) composition is chief among what determines the effectiveness of the thin film or sputtering disposition.

As regard gaseous ion, argon is commonly used to initiate and ionize the process. However, there are situations where it is not best suited for the job.

For instance, if the target consists of a heavier or lighter composition, gaseous ions such as krypton or neon will prove more effective.

For this reason, clients who need the services of manufacturers or suppliers should ensure they deal with those that understand these technicalities. This will enable them to make durable and effective targets.

The 3 Best Sputtering Target Suppliers

Frankly, choosing the best suppliers in the business is a subjective task. As a result, you should not be surprised to see a different opinion elsewhere.

Before we state our 3 best suppliers, you should be aware that yardsticks such as machinery, experience, wide range of clientele, are used to arrive at our choice. Below are our best 3 suppliers:

Process Materials Inc.

This company is located in Livermore, California, USA, and has been in the business since 1997. Their experience is not as vast as that of other competitors. They have however made up for this with quality services delivered to their clients.

Some of the clients they render service to are front liners in the automotive, aviation, chemical engineering, communications, imaging, and a few other industries.

Super Conductor Materials Inc.

This company is situated in Suffern, New York, USA. There have been active in the business since 1987. This validates how much experience and expertise they have gathered in this business.

They offer services that include the manufacture and supply of coat materials, semiconductor materials, infrared materials, sputtering targets, and a lot more.

Plasmaterials Inc.

This company was also established in 1987; they are highly skilled with a great wealth of experience. With years of excellence and commitment to improving, they have a lot of materials and metallurgical procedures that will suit various clients and projects.

You can visit https://www.plasmaterials.com/products/sputtering-targets/ for more information on this.

On a Final Note

A lot of products around you require the use of sputtering targets. Some of them include some kinds of glass, semiconductors, solar panels, and many more.

Just in case you are on the lookout for manufacturers or suppliers of such products, we have identified 3 of the best in this article. We have also shared some relevant information about the procedure and hope it will help you understand better how to appreciate the items around you.