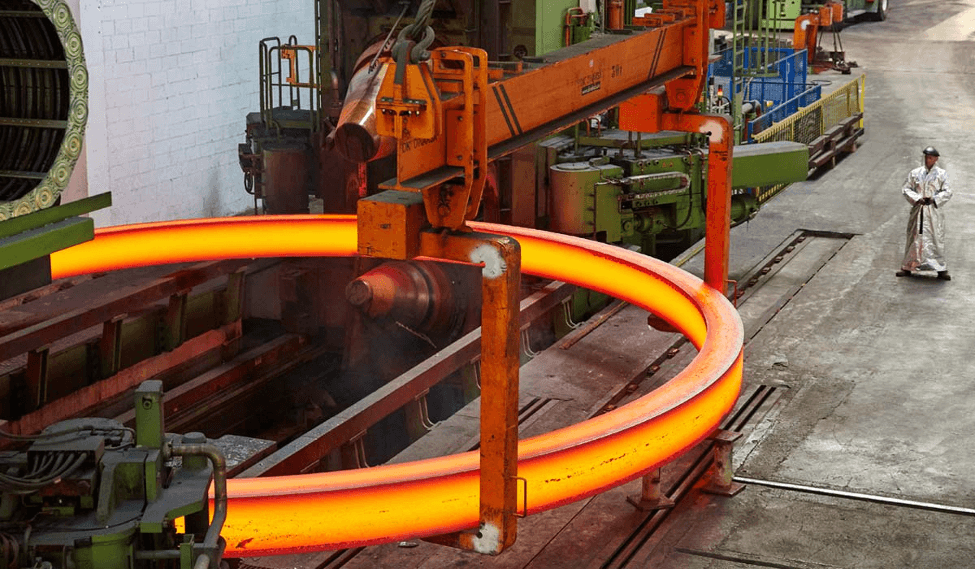

This metalworking process involves exerting high pressure on thick, solid, and round metal pieces to create thin rings.

The process can be performed on several types of metals including stainless steel, carbon steel, waspaloy, Hastelloy X, Inconel, and alloyed steel. The sizes of the rings vary hence their many applications.

Likewise, rolled ring forging process produces pieces with aligned grain flows and improved densities. While other metal forging processes may weaken with time, rolled rings are tough and resistant to any hostile environment.

In this article, we will discuss the major applications of rolled rings and their benefits.

Products produced using rolled ring forging

Rolled forged rings are seamless and widely versatile. You will find them in top machinery and equipment. The panels are designed to endure high temperatures, corrosion, and any harsh environment. Here are some of its applications:.

- Fracking process parts

Fracking involves the use of a hydraulic machine to exert tension on parts. Seamless rings are strong, long-lasting, and corrosion resistant, and do not crack or break at high temperatures. This makes them ideal for use in the fracking process. Their durability makes them extremely reliable and dependable.

- Connecting pipes

Petroleum and other oils are mainly transported through pipes. These pipes are connected safely to each other to prevent any leakage along the way. Rolled forged rings are used to secure the connections since they guarantee durability and no leaks. Likewise, you will find these parts in pressure vessels used in gas and oil production since they can withstand high pressure

- Wind turbines

Forged rings are essential in the construction of wind turbines. Their strength, precision, and accuracy make them a perfect choice for keeping wind turbines productive. The shafts of the wind turbines are supported by rolled rings so that they can withstand varying loads. Likewise, wind turbines are prone to wear and tear, which is why they are fitted with ring bearings to prevent breakage and energy loss. Other applications of rolled rings in wind turbines include couplings, gears, and flanges connecting tower units.

- Aircraft gearboxes

The gearboxes in an aircraft are responsible for the safety and welfare of pilots and passengers in the plane. As such, engineers must ensure the materials used are exceptionally strong and durable.

Forged metal alloys are used in manufacturing lightweight yet resilient and dependable bearings and gears that meet the plane requirements.

Likewise, the parts of an airplane are always subjected to high-velocity rotation and air pressure, which is another reason why industries use forged rings in major gears. On average, these rings are 33% stronger and 5 to 10% lighter than the welded parts. Read more here https://widetopics.com/11-advantages-of-seamless-forged-rolled-rings/

- Automotive products

The majority of automotive parts are designed to endure the high stress and load that comes with vehicle operations. To keep the vehicle running smoothly, engineers include forged parts and components in every part of the vehicle. This includes braking systems, camshafts, couplings, Crankshafts, and gears. Besides being torque resistant, the high-quality parts are versatile and lighter.

Benefits of rolled ring forging

Rolled rings are used in manufacturing almost every industrial product you will find in the modern world today. It is the goal of every company to access durable and versatile parts for their business. Such parts are guaranteed to withstand all environmental settings. Let’s look at the various benefits of rolled ring forging.

- Cost-effectiveness

Although the rolled ring forging process is extremely complex, the end products are quite affordable compared to any other fabrication methods. Most forging processes involve multiple pieces of machinery, which raises their cost. Seamless rolled rings, on the other hand, involve fast setup times and low tooling costs which reduces production costs.

- Strength

These components are popular for their incredible strength. Unlike cast or welded parts that are frail in harsh conditions, rolled rings can withstand and perform even in the most extreme conditions. The rings will stand out even in high pressure or extreme temperature. As such, they are common in oil refineries, jet engines, paper mills, and wind turbines. Fact that rolled rings are forged under high temperatures, the end products are exceptionally strong and resistant.

- High-temperature endurance

The formation process involves high temperatures that are near or at recrystallization. The handling of the metals impacts the endurance of the end product when subjected to extreme temperatures.

- Versatility

As mentioned, the uses of rolled rings are many. And the fact that the forged parts can be produced from multiple metal alloys, fits several applications. Click here to learn more.

Conclusion

The rolled ring forging process is growing popular by the day. Most manufacturing industries depend on it to produce accurate pieces, used in major machinery. Besides producing high-quality items, the rolled ring forging process is versatile, cost-effective, and reliable. Compared to castings or welded rings, rolled rings have a better grain structure and are immune to porosity.

Read More: How many jobs are available in industrial machinery/components.